Pet Bottles Plastic PP PE Film Metal Crusher Paper Wood Plastic Machine Recycling Machinery Single Shaft Shredder Guanulator Plant

3E MACHINERY's (WT22/30/40 series) single shaft shredder is a widely used type of recycling machine. It's an ideal machi

Basic Info.

| Model NO. | WT2260 |

| Painting | Variety of Coating Solutions |

| Transport Package | Standard Seaworthy Packing(Wooden Box/ Nude Pack) |

| Specification | According to the actual size |

| Trademark | 3E |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 200 PCS/Year |

Product Description

3E MACHINERY's (WT22/30/40 series) single shaft shredder is a widely used type of recycling machine. It's an ideal machine widely used in plastics, paper, wood, fiber, rubber, organic waste and non metallic materials. It consists of a single solid shaft with square blades bolted into it. This shaft rotates at about 74-83 RPM, depending on the model, and these blades pass through a bed knife on the base of the cutting chamber. A hydraulic ram continually pushes the material against the shaft of the shredder for continuous cutting. It is almost always used with a screen, which retains the material in the cutting chamber to reduce the material even further. And the standard cut on a single shaft shredder is 25-40mm.The size of the machine required for requirements of each client and project, such as depends on the initial size of the material, capacity and the final output size etc.

Application

WT40 series suitable for processing a wide range of PET bottle, films, plastic lump/purging, plastic boards, plastic flake, plastic barrels, paper, circuit boards, wood, fibre, rubber, cables and WEEE.

Specification

WT40 series is our conventional range of small-middle size single shaft shredders. Controlled by microcomputer (PC), featuring start, stop, reverse functions. It is fitted with an automatic overload return mechanism to prevent damage to rotor and other parts. And It has advantage of high efficiency, low noise and economical etc.

| Model | WT2260 | WT3080 |

| Item | ||

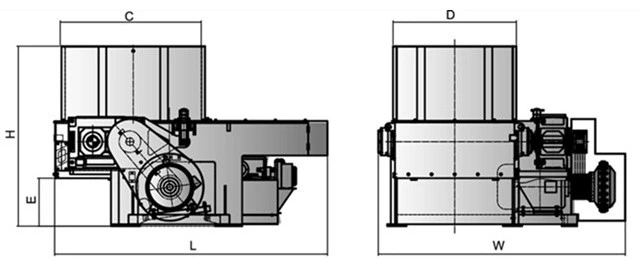

| Dimension L/W/H(mm) | 1840×1379×1754 | 2500×1720×1700 |

| Cutting Chamber C/D(mm) | 857×600 | 1200×800 |

| Height of discharge port E(mm) | 546 | 500 |

| Cylinder Stroke(mm) | 500 | 750 |

| Rotor Diameter(mm) | φ224.7 | φ300 |

| Main Shaft Speed (r/min) | 83 | 83 |

| Screen Mesh(mm) | φ25 | φ40 |

| Rotor-knives(PCS) | 32 | 46 |

| Stator-knives(PCS) | 2+2 | 2 |

| Main Motor Power(KW) | 18.5 | 30 |

| Hydraulic Motor Power(KW) | 2.2 | 2.2 |

| Weight(KG)Approx | 1600 | 2600 |

| Model | WT4080 | WT40100 | WT40120 | WT40150 |

| Item | ||||

| Dimension L/W/H(mm) | 2838×1779×1875 | 2838×2036×1880 | 2843×2564×1975 | 2825×2886×2103 |

| Cutting Chamber C/D(mm) | 1410×800 | 1410×1000 | 1410×1200 | 1410×1500 |

| Height of discharge port E(mm) | 500 | 500 | 500 | 560 |

| Cylinder Stroke(mm) | 900 | 900 | 900 | 900 |

| Rotor Diameter(mm) | φ390.3 | φ390.3 | φ390.3 | φ390.3 |

| Main Shaft Speed (r/min) | 74 | 74 | 74 | 74 |

| Screen Mesh(mm) | φ40 | φ40 | φ40 | φ40 |

| Rotor-knives(PCS) | 46 | 58 | 70 | 90+4 |

| Stator-knives(PCS) | 2 | 2 | 2 | 3 |

| Main Motor Power(KW) | 37 | 45 | 55 | 75 |

| Hydraulic Motor Power(KW) | 2.2 | 2.2 | 5.5 | 5.5 |

| Weight(KG)Appox | 3300 | 3900 | 5400 | 5800 |

Features

- Rotor: Various rotor configurations available for processing a wide range of materials. Blades are made from hardened DC53 steel, the blades can be turned 4 times before changing.

- High performance rotor- The rotor is our standard rotor, suitable for processing a wide range of materials at high speed. Materials include plastics, wood, paper, fibre, cable, etc;Hard material rotor- The rotor is designed specifically for processing hard materials such as ABC, PC, Nylon, etc. The blade holders are sub-set deeper into the shaft to reduce the impact on the blades and shaft;Film rotor- The rotor is designed specifically for processing films. Sub-set block blades in the shaft prevent film from wrapping around the rotor and hardox surface on the rotor protects the shaft against abrasion from sand and dirt.

- Gearbox: Water cooled gearbox guards against overloading. Hardened teeth on the reducer.

- Shock Absorbe: Absorbs vibrations caused by the shredding of the material. This protects the machine and its various parts from damage.

- RAM: The hydraulic ram pushes material against the rotor.

- Bearing Seat: Protective bearing covers to avoid foreign contamination entering the bearing housing. Grease points to release oil at intervals to increase service life.

- Screen: Various screen sizes.

- Hydraulic Station: The ram pressure and timing can be adjusted to suit different materials. From WT40 series and above the machine can be fitted with wind cooled two-speed pump.

Certification

3E MACHINERY was awarded 18utility model patents and 3 invention patents.

Our service1.Pre-sale support 3E Machinery consists of experienced specialists, we will offer a suitable solution according client's requirement in time. On-site inspection.2. After-sale service 3E's skilled technicians are available to assist with onsite installation, commissioning & training on request. This will enable customers to optimize the performance of their new plant. Customers will be briefed on all aspects relating to operation and maintenance by a 3E technician. Dimensional drawings together with service requirements will be provided prior to delivery of the equipment. This will allow the customer to prepare the site and allow them to commence production in a timely fashion. 3E holds a adequately inventory of spare parts and their efficient service personnel will ensure that any required part will be dispatched without delay. Delivery of the spare parts may be by air, sea or courier depending on the urgency of the situation. Customers are encouraged to hold their own critical spare parts such as granulator blades and screens to ensure optimal machine condition and performance.3. Technical support 3E provides enough hardware resource especially for large-scale production lines, clients can carry out installation, commissioning and acceptance before delivery. Regular return visit.

Advanced production and testing equipments

3E MACHINERY equipped with advanced processing and testing equipments, in order to ensure the quality of the products. And strictly control the quality of each parts, efforts to provide the best quality products to our clients.Company profile

3E GROUP is an integrated company specialized in developing, manufacturing, distributing and providing recycling machinery solutions. Our main entity " Guangzhou 3E Machinery CO. Ltd" founded in 2003, has currently become focusing on "Shredding" and "Recycling industry" modern enterprise.Technology is the core-competitiveness of 3E Group, we are active in the recycling market and keep cooperating with well-known enterprises in Europe and the USA. Meanwhile, 3E Group keeps on improving and innovating, so far, we awarded 18utility model patents and 3 invention patents."Efficient Economical & Environmental" is the traditional idea of 3E Group. With its own intellectual property and solid technological team, our products have been already sold to over 90 regions and countries which include the USA, Europe, Australia, Southeast Asia, Latin America, and Middle East.

Send to us