Double Shaft Shredder for Waste E

Package Size 340.00cm * 220.00cm * 80.00cm Package Gross Weight 1200.000kg WLS series two-shaft shredder The WLS series

Basic Info.

| Model NO. | WLS-1000 |

| Object | Aluminum Cans;Carton,Plastic Bottles/Drums;Branch |

| Drive | Electric/Hydraulic |

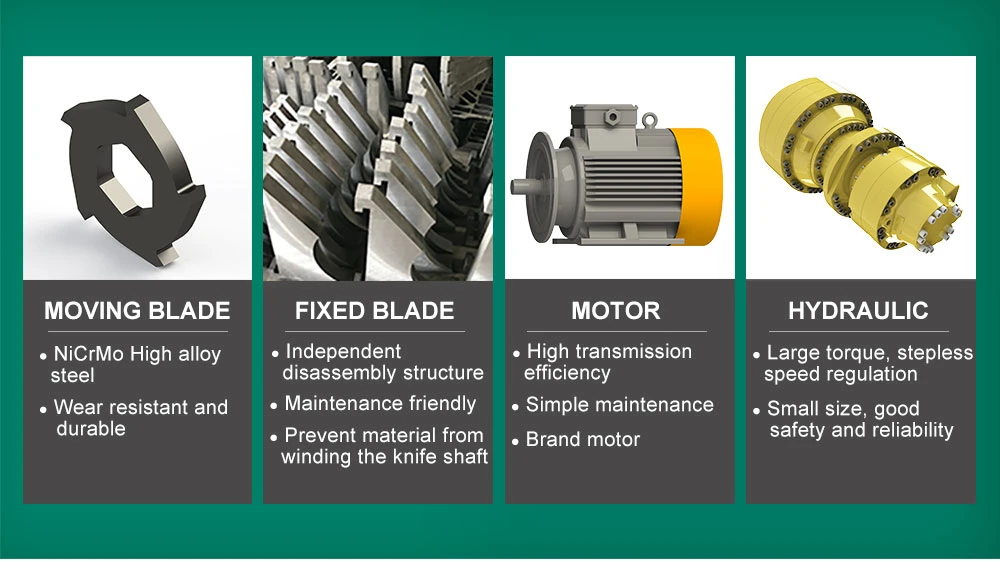

| Cutter Material | Nicrmo High Alloy Steel |

| Automation | Full-Automatic |

| Voltage | as Per Request |

| Control System | Siemens |

| Test Video | as Your Needs |

| Computerized | Computerized |

| Chamber Size | 1010*700mm |

| Bearing | Zwz |

| Hopper Opening Size | 1700*1300mm |

| Blade Diameter | 29mm |

| Power | 30+30kw |

| Transport Package | Film with Wooden Pallet |

| Specification | 3200*2038*2482mm |

| Trademark | WALI |

| Origin | Anhui Province, China |

| HS Code | 8477800000 |

| Production Capacity | 260sets/Year |

Packaging & Delivery

Package Size 340.00cm * 220.00cm * 80.00cm Package Gross Weight 1200.000kgProduct Description

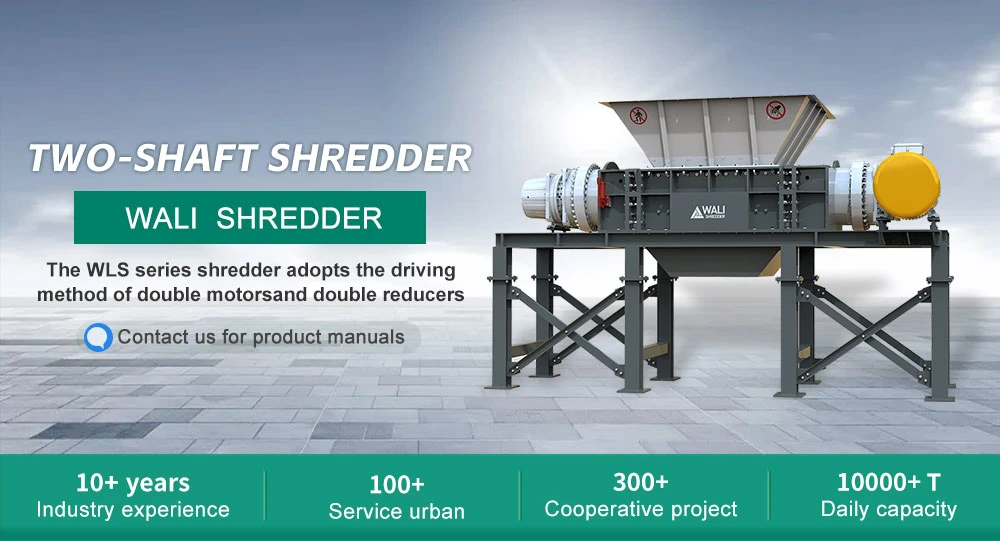

| Model | Power(kW) | Blade thickness (mm) | Chamber size (mm) | Machine size (mm) |

| WLS-800 | 15 | 20/30/50 | 800*530 | 2180*2559*1380 |

| WLS-1000 | 22-37 | 30/40/50 | 1000*750 | 3200*2038*2482 |

| WLS-1200 | 45-75 | 40/50/60 | 1200*850 | 4000*2420*2682 |

| WLS-1600 | 75-132 | 50/60/80 | 1600*1000 | 4928*2720*2998 |

| WLS-1800 | 75-110 | 50/60/80 | 1800*1000 | 6028*2714*3118 |

| WLS-2000 | 200 | 50/60/80 | 2100*1270 | 6660*3670*3651 |

The WLS series two-shaft shredder adopts the driving method of double motors and double reducers, and has stronger power for shredding capacity to meet customers' greater capacity needs.The power of WLS series shredder is 44kW-300kW.It is a heavy-duty shearing shredder, suitable for processing solid waste with large volume and high hardness.

WALI GROUP located in Anhui Province,China. We set up our own team and factory in this beautiful city.As a professional equipment manufacturer,WALI GROUP adhere to strict production standards. Obtained ISO9001 certificate and CE certificate. We has been dedicated to the design and manufacturing of solid waste recycling equipment for decades. Provide equipment R&D service,lifelong technical support and complete pre- and after-sale service. To provide customers with high quality and the most cost-effective products, to help them maximize benefits is our constant purpose.Wali Environment Protection,Better Future,Better Earth!

Q:Are you a factory or a trade company?

A:We are a manufacturer with our own factory in Ma'anshan, Anhui Province, China. Welcome to take a visit!

Q:How to choose a shredder machine?

A:Our technical consulting services can help, recommend the most suitable machine and program according to your needs, capacity, site and other actual situation.

Q:How about the service?

A:We provide after-sales service, including on-site installation, commissioning equipment, guidance and training of operators etc. Make regular return visits to solve your equipment problems and optimize your equipment maintenance methods.

Q:How long is your delivery time?

A:Generally, it will be about 20-35 working days after deposit, which also will affected by the actual situation of the project.

Q:Which trade terms is available?

A:FOB, CFR,CIF, EXW and other terms based on your needs.

Send to us