Automatic Resin Feeder Plastic Material Feeding Machine Vacuum Hopper Loader for PP PE Pellets

Basic Info.

| Model NO. | XC-VAL300G |

| Static Wind Pressure | 1300 mm/H2O |

| Controller | Microcomputer |

| Usage | Industry Plastic |

| Conveying Capacity | 300 Kg/H |

| Loading Distance | 3.5 M |

| Motor | 1.3HP/1.1kw |

| Transport Package | Wooden Case as Usual |

| Specification | 390x290x560 mm |

| Trademark | XIECHENG |

| Origin | Jiangmen, Guangdong, China |

| HS Code | 84282000 |

| Production Capacity | 500 Per Month |

Packaging & Delivery

Package Size 39.00cm * 29.00cm * 56.00cm Package Gross Weight 14.000kgProduct Description

Automatic Resin Feeder Plastic Material Feeding Machine Vacuum Hopper Loader for PP PE Pellets

Product Description

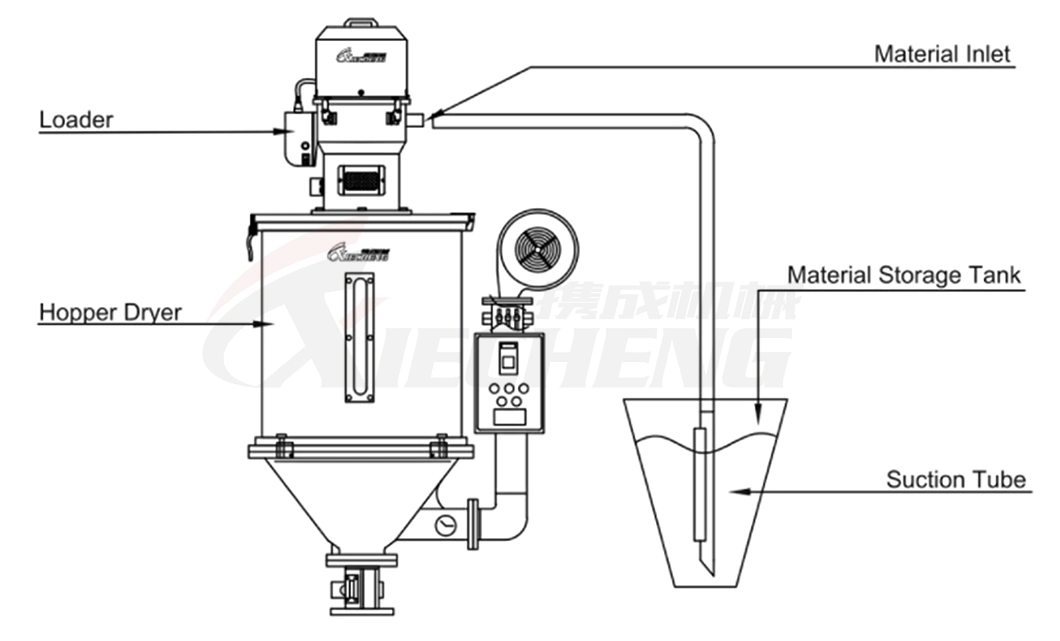

Euro Hopper Loader

Self-contained hopper loaders are Euro design with stainless steel hopper to avoid material contamination. In addition, it has an attractive appearance, a sound-proof motor cover to reduce noise level and a top handle to enable convenient movement. Also the remote operation has been realized by using a detachable control panel.

Product Specifications

| Model | XC-X300G | |

| Motor | Model | Carbon Brush |

| Specification | 1.1kw/1.3hp 1φ | |

| Conveying capacity (kg/hr) | 300 | |

| Loading Distance (m) | 3.5 | |

| Static Wind Pressure (mm/H2O) | 1300 | |

| Storage Tank Capacity (L) | 7.5 | |

| Conveying Tube Inner Diameter (mm) | φ38 | |

| The Attached Hoses (mm) | φ38mm×3.5m 1pcs | |

| Dimensions L x W x H(cm) | 42x34x57 | |

| Weight (kg) | 12 | |

If you want more sizes, please contact us for details

CONTACT SUPPLIER

Product Details

01 Motor

Adopted carbon brush motor, high rotating speed, large air volume, small size, convenient to move and easy to install.

02 Controller

Cable remote controller, easy to operate, with auto cleaning function.

03 Stainless Steel Material

All stainless steel contact parts, to ensure no pollution in material conveying.

04 Filter System

With cloth type filter and auto spray cleaning and dust removal device, to extend the service life of the motor.

05 Humanized Design

Hopper and bottom base can be adjusted by any direction.

06 Magnetic Reed Switch

Adopt magnetic reed switch to control, sensitive induction and stable operation.

Application Range

About Us

Company ProfileIn 2009, founded by Mr. Fuzhibo with its head quarter in Jiangmen city which known as a famous hometown of many overseas Chinese, Guangdong Xiecheng Intelligent Equipment Co.,Ltd. has been devoted herself to be an integrated enterprise of R&D, manufacturing and marketing businesses for High-end Industrial Refrigeration Equipment, Rubber and Plastic Moulding Auxiliary Automation Equipment, and also Intelligent Integrated System Solutions. Authenticated by IS09001, XIECHENG also successfully established the "6+1+C" full dimensional product service system with her own supply chain advantages of combining the six series of products, as Industrial Refrigeration, Mould Temp. Controlling, Material Conveying, Crushing & Recycling, Dehumidifying & Drying, and also Mixing, into central intelligent system solutions as Material Feeding, Air Supply, Water Supply and Power Supply, to fast fitting customers' specific demands.